MK74 Powder Flame Spray System

Overview

MK74 Powder Flame Spray System

Weighing only 1.85kg (4Lb), the Metallisation MK74 powder spray pistol can be hand held or machine mounted to spray a wide range of powders. Its robust construction will ensure long periods of trouble-free operation.

The MK74 is easy to ignite and has excellent flame stability, thanks to its nozzle system. A special air cap narrows the spray pattern to densify the coating which is particularly beneficial when spraying ceramics where very high deposit efficiencies can be achieved.

The MK74 can spray ceramic coatings as well as self fluxing alloys and all other metallic powders.

Features

- High deposit efficiency

- Dense coatings

- Quiet operation

- Sprays ceramics and metals

- Simple to use

- Suitable for spray/fuse coatings

- Powder vibrator option for poor flowing powders

- Optional remote powder feeder

- Can spray some plastics

- Economic coatings

MK74-PF Documents

Applications

- Small engineering repairs

- Spray/fused coatings

- Shaft reclamation

- Self fluxing alloys for extreme wear applications

- Glass mould plungers

- Steel mill table rolls

Accessories

Accessories can help the operator and increase productivity.

Videos

None

Flame Spray Process

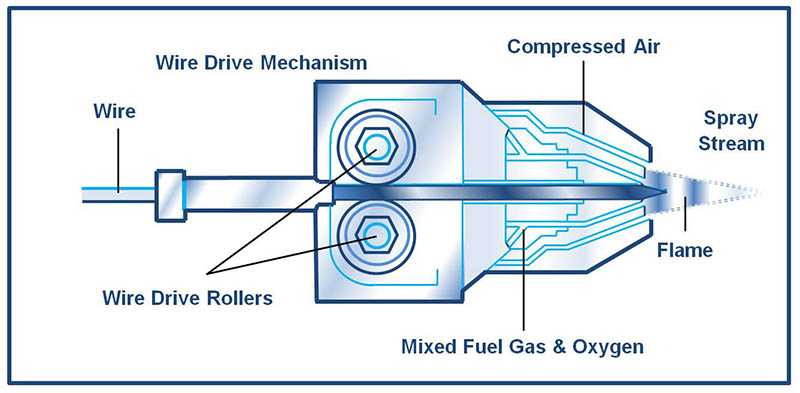

Flame spray is a process that uses an oxy-fuel flame to melt wires and in some cases powders or ceramic rods.

The molten material is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed. Anti-corrosion coatings are typically applied with oxy-propane systems.

Engineering coatings are typically applied with oxy-acetylene systems. Where propane is not available, oxy-acetylene systems can apply anti-corrosion coatings.

Flame spray systems are commonly manually operated but it is possible to semi-automate or fully-automate the process if required.

Metallisation have a full range of wire, powder and ceramic rod flame spray systems in hand-held or automated versions.