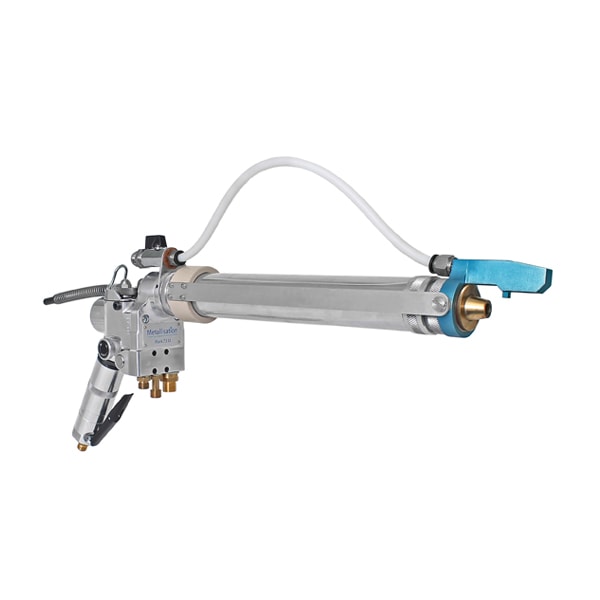

MK73-FS Wire Flame Spray System

Overview

The Metallisation MK73-FS is an oxygen-propane fuelled flamespray system giving un-rivalled anti-corrosion coatings.

The lightweight, well-balanced, robust pistol offers the quickest spray rates on the market, saving you both time and money. Systems can be supplied as continuous spray or, more commonly, with a unique stop/start function that allows the operator to stop spraying but keep the flame lit without damage to the pistol.

The ‘site friendly’ control panel is more robust and offers further protection to the flowmeter and ARF unit. It can be wall mounted or will free-stand (FS) on the floor. The flow of hoses is neater than the previous unit.

The control panel is also better suited to using in long supplies format, which is becoming an increasing requirement for site installations. See ‘Supplies Packs and ‘Control Board’ section for more details.

The pistol can be further enhanced by fitting a deflected spray extension. This unit allows the operator to spray at right angles and get into difficult to access spray areas, such as between pipes or close to brackets. This enables more areas to be sprayed and with a better quality coating than may have previously been possible. The extension uses the same consumable parts as a standard pistol.

Features

- Fastest pistols on the market (up to 50kg/hr for continuous zinc)

- Stop/start version allows operator to stop spraying and leave the flame lit (e.g., while inspecting or moving the work piece)

- Variety of hose lengths to suit each application

- Wide range of wire sizes to suit many application and coating requirements

- Spreader and non-spreader versions to allow detail work or larger areas to be sprayed efficiently

- Free standing or wall mounted control panel

- Safety shut-off valve

- Optional panel mounted oxygen regulator for long supplies setups

- Variable wire speed control

- Suitable for anti-corrosion wires plus some steels, copper and bronzes.

- Two stage air cap gives optimal setting for lighting and spraying

- Rugged construction combined with light-weight and balance for ease of handling

- Hanging hook for temporary storage or connection to spring balance

- Flow meters for optimal setting of parameters and fault finding

- Flow meters include large pointers for ease of checking from a distance

- Air Regulator and Filter (A.R.F.) unit supplies motor air, nozzle air

- Optional deflected extensions for access to difficult to spray areas

MK73-FS Documents

Applications

- Structural Steelwork

- Offshore Platforms

- Marine Applications

- Bridges

- Fences and Gates

- Tanks and Vessels

- Street Furniture

Accessories

Accessories can help the operator and increase productivity.

Videos

MK73-FS Wire Flame Spray System

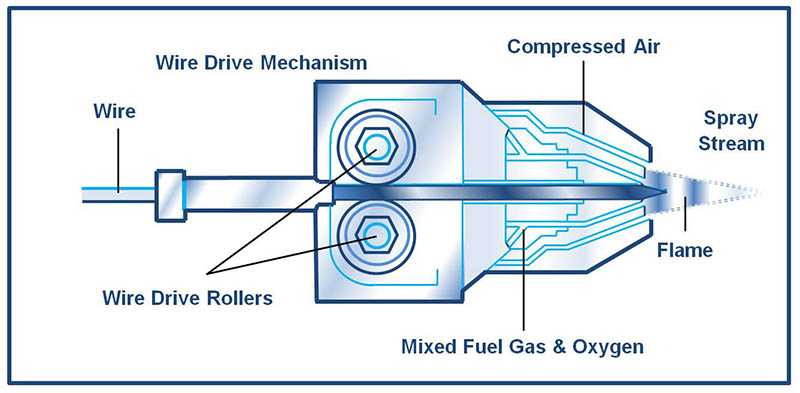

Flame Spray Process

Flame spray is a process that uses an oxy-fuel flame to melt wires and in some cases powders or ceramic rods.

The molten material is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed. Anti-corrosion coatings are typically applied with oxy-propane systems.

Engineering coatings are typically applied with oxy-acetylene systems. Where propane is not available, oxy-acetylene systems can apply anti-corrosion coatings.

Flame spray systems are commonly manually operated but it is possible to semi-automate or fully-automate the process if required.

Metallisation have a full range of wire, powder and ceramic rod flame spray systems in hand-held or automated versions.