MK74-PCC Flame Spray System

Overview

The Metallisation MK74-PCC is a fully automatic flamespray system with mass flow control, which offers the ability to produce the highest quality, repeatable coatings.

The system provides a fully automatic sequence of flame, powder feed and purge. Fault sensors check for loss of flame, stoppages or powder out and can interlock to external automation to stop production and request assistance. These features ensure continued operation, improved coating quality and minimised downtime.

The system is PC controlled with distributed I/O, for extreme reliability, comprising a touch screen HMI (with optional keyboard), mass flow control gas box, and compact, electric drive pistol.

Features

- Mass flow control of Oxygen, Fuel Gas and Air

- Easy to use, intuitive operator interface

- PC control with touch screen

- Optional keyboard control or operator interface unit

- Unlimited recipes and parameter recording

- Manual or fully sequenced start-up, operation, and shut-down

- Safety interlocks to prevent running without Nozzle Air

MK74-PCC Documents

Applications

- Aerospace

- Abradables

- Thermal barriers

- Spray/fused coatings

Accessories

Accessories can help the operator and increase productivity.

Videos

None

Flame Spray Process

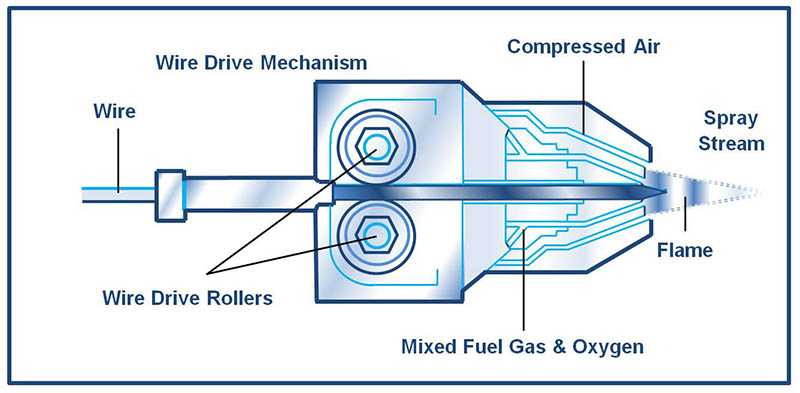

Flame spray is a process that uses an oxy-fuel flame to melt wires and in some cases powders or ceramic rods.

The molten material is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed. Anti-corrosion coatings are typically applied with oxy-propane systems.

Engineering coatings are typically applied with oxy-acetylene systems. Where propane is not available, oxy-acetylene systems can apply anti-corrosion coatings.

Flame spray systems are commonly manually operated but it is possible to semi-automate or fully-automate the process if required.

Metallisation have a full range of wire, powder and ceramic rod flame spray systems in hand-held or automated versions.