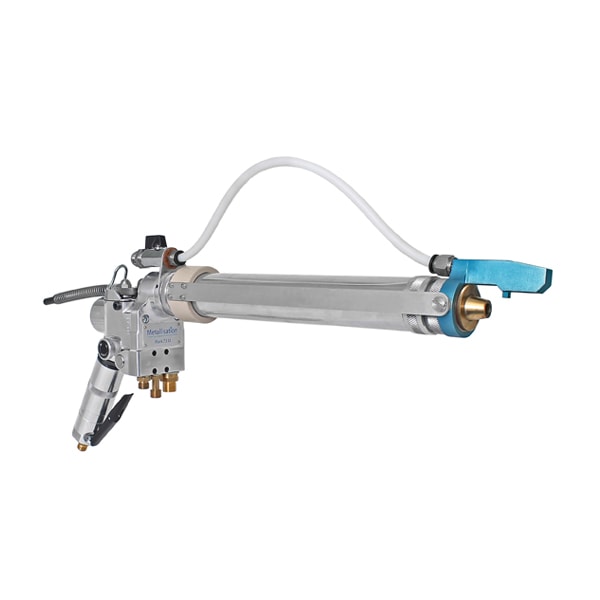

MK61-FS Flame Spray System

Overview

The Metallisation MK61-FS is an oxygen-acetylene fuelled flamespray system, primarily for spraying engineering coatings of steels, bronzes, copper and importantly, molybdenum.

The lightweight, robust pistol offers the possibility to reclaim damaged parts for small to medium sized applications. Molybdenum can also be sprayed with the MK61-FS as a soft bond coat through to a very hard, wear resistant coating. The MK61-FS system can be used for anti-corrosion coatings where propane is not readily available.

Extended supplies package options are being increasingly used to maximise efficiency when working on large job sites such as refineries, petro-chemical sites and offshore structures. The extended supplies packages, up to 50m from cylinders to pistol, allows the cylinders to be remotely located while the operator moves around the job with just the pistol and occasionally moving the control panel. The length of supplies is limited by the pressure of the acetylene. Longer supplies are possible with the propane fuelled MK73-FS as well as faster spray rates for corrosion coatings.

The ‘site friendly’ control panel is more robust and offers further protection to the flowmeter and ARF unit. It can be wall mounted or will free-stand (FS) on the floor. The flow of hoses is neater than the previous unit.

Features

- Stop/start version allows operator to stop spraying and leave the flame lit (e.g., whilst inspecting or moving the work piece)

- Wire sizes 1.5mm to 4.76mm (3/16”) to suit many application and coating requirements

- Suitable for Engineering wires, steels, copper and bronzes plus anti-corrosion materials.

- Spreader and non-spreader versions to allow detail work or larger areas to be sprayed efficiently

- New, free standing or wall mounted control panel with Safety shut-off valve

- Optional panel mounted oxygen regulator for long supplies setups

- Variable wire speed control

- Two stage air cap gives optimal setting for lighting and spraying

- Rugged construction combined with light-weight and balance for ease of handling

- Variety of hose lengths to suit each application

- Flow meters for optimal setting of parameters and fault finding

- Flow meters include large pointers for ease of checking from a distance

- Air Regulator and Filter (A.R.F.) unit supplies motor air, nozzle air.

- Optional deflected extensions for access to difficult to spray areas (anti-corrosion wires)

- Variety of wire dispense methods and packaging available

MK61-FS Documents

Applications

- Engineering coatings

- Reclaiming parts

- Bearing and seal surfaces

- Wear coatings

- Molybdenum

- Fine coatings with low heat input

Accessories

Accessories can help the operator and increase productivity.

Videos

MK61-FS

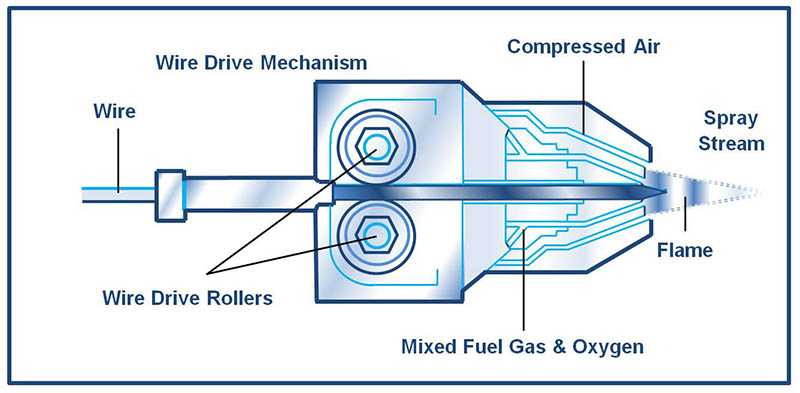

Flame Spray Process

Flame spray is a process that uses an oxy-fuel flame to melt wires and in some cases powders or ceramic rods.

The molten material is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed. Anti-corrosion coatings are typically applied with oxy-propane systems.

Engineering coatings are typically applied with oxy-acetylene systems. Where propane is not available, oxy-acetylene systems can apply anti-corrosion coatings.

Flame spray systems are commonly manually operated but it is possible to semi-automate or fully-automate the process if required.

Metallisation have a full range of wire, powder and ceramic rod flame spray systems in hand-held or automated versions.